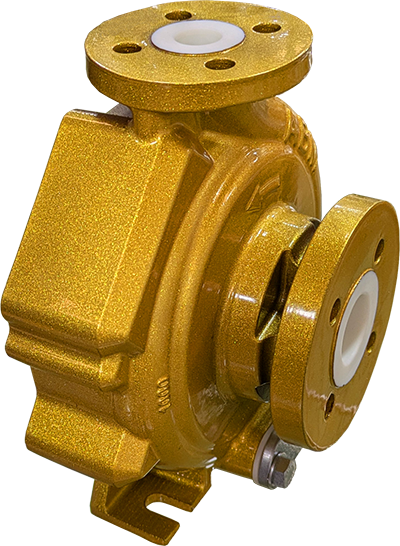

Casing

Combining a ductile iron casing with a fully bonded ETFE lining in an ANSI pump creates a robust and versatile solution that brings together the structural strength of ductile iron and the chemical and abrasion resistance of ETFE. Here are some of the key benefits of this configuration:Learn More

Strong & Impervious

- Our ETFE lining is rotationally molded and securely bonded to a ductile iron casing, providing exceptional strength and superior chemical resistance.

- Rated for full vacuum

- Designed from the ground up to have industry leading liner thickness for the ultimate in permeation protection!

Abrasion Resistance

- The ETFE lining offers excellent resistance to abrasion and erosion, which is particularly beneficial in applications where the pump handles abrasive slurries or particulates. This minimizes wear on the pump casing and helps maintain performance over time.

- The protective ETFE layer minimizes internal wear and reduces the frequency of maintenance interventions. This results in lower long-term operating costs and less downtime, making the pump more reliable in continuous or critical applications.

Cost Savings

- Although the initial investment might be higher than standard casings, the extended service life, reduced maintenance costs, and minimized downtime contribute to significant long-term savings. The pump’s reliable performance also reduces the risk of costly process interruptions.

- All our current and planned future pump lines will work with the same casing. This can save you a significant amount when your chemical processing needs change.

Extra Thick Casing Lining

- Our ETFE lining is fully bonded to the ductile iron casing with an industry leading minimum thickness of 3/16".

- These two features provide the ultimate in permeation protection!

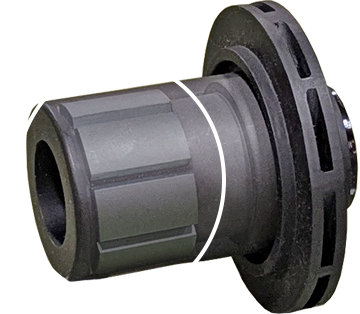

Impeller Assembly

Combining a ductile iron casing with a fully bonded ETFE lining in an ANSI pump creates a robust and versatile solution that brings together the structural strength of ductile iron and the chemical and abrasion resistance of ETFE. Here are some of the key benefits of this configuration:Strong & Impervious

- One-piece impeller and magnet assembly ensures maximum power transmission. There are absolutely NO shroud rivets or welding lines to fail.

- The tandem sintered silicon carbide radial bearings are separately mounted for optimal alignment and process lubricated . They’re individually replaceable and maintained in the correct position with a PTFE center spacer.

Powerful Magnets

- Powerful neodymium iron boron (NdFeB) magnets provide exceptional torque to prevent decoupling.

- They are first encased in 316L stainless steel before being injection molded with carbon filled ETFE into the impeller, which creates a double seal for superior resistance to permeation and corrosion.

Containment Shell & Shaft

One-piece composite containment shell has zero eddy current losses for maximum efficiency. • Outer aramid/vinyl ester shell for strength • Inner carbon fiber reinforced ETFE for optimal leakage protection and chemical compatibilityBullet Proof

- The outer shell is made from a aramid fiber and vinyl ester composite for maximum strength

- It can withstand burst pressures over 205 bar (3,000 psi), protecting against water hammer damage.

- Composite construction also eliminates eddy current losses, which boosts overall efficiency, especially for electrically conductive fluids.

Cantilevered Shaft

- The pump shaft, made from sintered alpha silicon carbide, is oversized to handle all radial loads effectively.

- Its stationary cantilevered design avoids using suction-blocking supports, maximizing fluid flow and reducing NPSHR.

- Allows the inner magnet (attached to the impeller) to rotate freely while being driven by the outer magnet.

Chemical Resistance

- Made from carbon fiber reinforced ETFE to resist corrosion and make it suitable for aggressive chemicals or high-purity applications.

- Acts as a hermetic barrier, eliminating the risk of leaks associated with traditional mechanical seals.

Containment Ring

The containment ring provides structural reinforcement to the containment shell, which encloses the inner magnet and prevents fluid from leaking out of the pump. The containment ring enhances the pump’s durability and pressure resistance while maintaining the benefits of a seal-less, leak-free design.Motor Alignment

- Keeps the motor and pump in perfect alignment to optimize magnetic coupling efficiency.

Easy Installation

- Simplifies maintenance by allowing quick motor replacement without disturbing the pump.

Reduces Vibration

- Helps dampen vibrations and absorb mechanical stresses, enhancing pump longevity.

- Designed to withstand corrosive environments, high temperatures, and operational stresses in industries like chemical processing and pharmaceuticals.

Outer Magnet

The outer magnet connects to the motor shaft and uses powerful neodymium iron boron magnets to couple with the inner magnet assembly.Extremely Strong

- Powerful neodymium-iron-boron magnets optimize torque transfer between the magnetic couple.

- Encased in iron and stainless steel for protection.

- Uses a powerful magnetic field to drive the impeller without a direct mechanical connection.

Transmits Torque

- Connects to the inner magnet with a powerful magnetic field to drive the impeller without a direct mechanical connection.

Eliminates Shaft Seals

- Since there’s no shaft penetration through the pump casing, it eliminates seal failures and leakage risks.

- Ideal for hazardous, toxic, or ultra-pure fluids since there’s no risk of external contamination.

- Without mechanical seals or packing, the pump experiences fewer wear-related issues, lowering downtime and costs.

Motor Adapter

The motor adapter provides a secure and precise connection between the pump and the motor, ensuring proper alignment and efficient power transmission. It acts as a mounting interface that holds the motor in place while maintaining the correct distance and positioning for the magnetic coupling system to function effectively.Motor Alignment

- Keeps the motor and pump in perfect alignment to optimize magnetic coupling efficiency.

Easy Installation

- Simplifies maintenance by allowing quick motor replacement without disturbing the pump.

Reduces Vibration

- Helps dampen vibrations and absorb mechanical stresses, enhancing pump longevity.

- Designed to withstand corrosive environments, high temperatures, and operational stresses in industries like chemical processing and pharmaceuticals.

© Copyright 2025 ABM Industrial - All rights reserved.