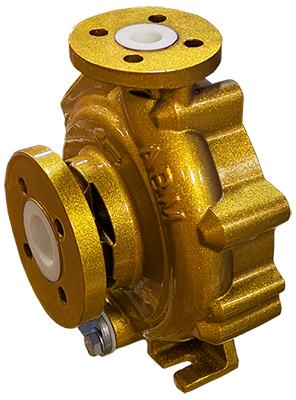

CASING

Combining a ductile iron casing with a fully bonded ETFE lining in an ANSI pump creates a robust and versatile solution that brings together the structural strength of ductile iron and the chemical and abrasion resistance of ETFE. Here are some of the key benefits of this configuration:Corrosion Resistance

- The combination of ductile iron’s mechanical strength and ETFE’s chemical resistance makes these pumps well-suited for a wide range of industries, including chemical processing, wastewater treatment, mining, and other applications where fluids can be both corrosive and abrasive.

- With minimal leakage, the risk of accidental releases of hazardous or flammable fluids is significantly reduced. This contributes to a safer work environment and aids in compliance with environmental and safety regulations.

Abrasion Resistance

- The ETFE lining offers excellent resistance to abrasion and erosion, which is particularly beneficial in applications where the pump handles abrasive slurries or particulates. This minimizes wear on the pump casing and helps maintain performance over time.

- The protective ETFE layer minimizes internal wear and reduces the frequency of maintenance interventions. This results in lower long-term operating costs and less downtime, making the pump more reliable in continuous or critical applications.

Cost Savings

- Although the initial investment might be higher than standard casings, the extended service life, reduced maintenance costs, and minimized downtime contribute to significant long-term savings. The pump’s reliable performance also reduces the risk of costly process interruptions.

- All our current and planned future pump lines will work with the same casing. This can save you a significant amount when your chemical processing needs change.

Extra Thick Casing Lining

- Our ETFE lining is fully bonded to the ductile iron casing with an industry leading minimum thickness of 3/16".

- These two features provide the ultimate in permeation protection!

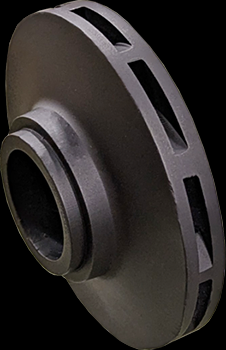

Impeller

The AP-S pump impeller is a precision-engineered component designed for optimal fluid handling. Here's a breakdown of its key functions:Single Piece

- The AP-S impeller is made of carbon filled ETFE Injection molded in a single piece for the ultimate in strength and durability.

- There are no shroud rivet or welding line to fail.

Unobstructed

- Enclosed impeller with unobstructed eye delivers high efficiency and low NPSHR.

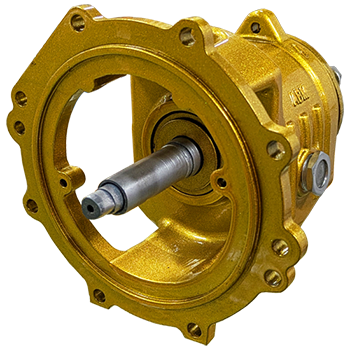

Back Cover

The back cover seals the casing with structural strength of ductile iron and the chemical and abrasion resistance of molded ETFE.Perfect Alignment

- Keeps the shaft in perfect alignment to optimize coupling efficiency.

ETFE Lined

- Lined with ETFE for the ultimate in chemical corrosion resistance.

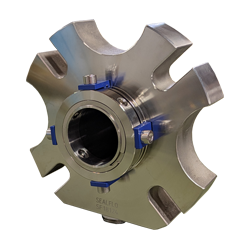

MECHANICAL SEAL

Mechanical seals are a popular choice for ANSI pumps because they provide a robust, efficient, and reliable method for sealing the pump’s rotating shaft. Incorporating a mechanical seal on an ANSI pump not only improves sealing efficiency and safety but also contributes to energy savings, longer equipment life, and reduced maintenance—making it a cost-effective choice over the long term. Here are some of the key benefits:Leakage Prevention

- Mechanical seals create a tight, controlled barrier between the process fluid and the external environment. This minimizes or virtually eliminates the leakage that can occur with traditional packing seals, which is particularly important when handling hazardous, corrosive, or high-value fluids.

- With minimal leakage, the risk of accidental releases of hazardous or flammable fluids is significantly reduced. This contributes to a safer work environment and aids in compliance with environmental and safety regulations.

Reduced Maintenance

- Mechanical seals, when properly selected and maintained, generally require less frequent adjustment than packing seals. Their improved sealing performance can lead to fewer unscheduled shutdowns and lower overall maintenance costs, helping to extend the pump’s service intervals.

- Because mechanical seals reduce the wear and tear on other pump components (such as bearings and shaft seals) by limiting fluid leakage and reducing friction, the overall lifespan of the pump can be extended. This also means less frequent replacements and repair costs.

Versatility

- Mechanical seals are available in various designs (single, double, etc.) and can be tailored to handle different pressures, temperatures, and chemical environments. This versatility makes them well-suited for the wide range of applications typically encountered in ANSI pump operations.

- High-quality mechanical seals can tolerate slight misalignments and help dampen vibrations, which contributes to smoother pump operation. This can reduce mechanical stress on the pump shaft and other components, leading to a more stable and reliable performance.

BEARING FRAME

The ANSI sealed pump bearing frame serves several critical purposes in centrifugal pumps designed to meet ANSI/ASME B73.1 standards (the standard for horizontal, end-suction centrifugal pumps). Here's a breakdown of its key functions:Shaft Support and Alignment

- The bearing frame houses the bearings that support the pump shaft, ensuring proper alignment between the impeller, shaft, and motor.

- This is important because misalignment causes vibration, premature wear, and catastrophic failure. The rigid bearing frame maintains precise shaft positioning even under operational stresses.

Contamination Protection

- The bearing frame incorporates various mechanical seals Blocks entry of dust, dirt, moisture, or chemicals from the environment. Prevent leakage of lubricant (grease/oil) from the bearing housing.

- This is critical for harsh industrial environments (chemical plants, refineries, wastewater treatment) where contamination would degrade bearings.

Mechanical and Thermal Stability

- Withstands radial and axial loads generated by the pump during operation. Resist deformation from temperature fluctuations (common in high-temperature processes).

- made of ductile iron for durability and long life.

© Copyright 2025 ABM Industrial - All rights reserved.