For nearly 40 years, we’ve been manufacturing and continuously improving ANSI non-metallic sealless mag-drive pumps, learning all the needs of our customers along the way. One thing we’ve figured out? No single pump design works best for every job. That’s why we now offer both sealed and sealless pumps—so you can choose what fits your needs.

Our sealless mag-drive pumps have become a customer favorite because they don’t leak, need little upkeep, and run reliably without mechanical seals. They’re a great choice when keeping fluids contained is a must—especially if you’re working with something corrosive or hazardous. With their leak-proof design, these pumps help keep things safe, clean, and efficient.

Our sealless mag-drive pumps have become a customer favorite because they don’t leak, need little upkeep, and run reliably without mechanical seals. They’re a great choice when keeping fluids contained is a must—especially if you’re working with something corrosive or hazardous. With their leak-proof design, these pumps help keep things safe, clean, and efficient.

However, as our experience has grown, we've recognized that there are situations where a sealed pump might be a more appropriate choice. Sealed pumps, by their very design, offer advantages in applications that require a robust barrier between the process fluid and the pump mechanics. This can be especially critical in industries where process conditions—such as extreme pressures or temperatures—demand an extra layer of containment or where maintenance protocols favor a sealed environment. Additionally, sealed pumps can sometimes handle fluids with particulates or varying viscosities more effectively, providing a level of versatility that complements the high-performance characteristics of sealless designs.

By offering two lines of pumps, we empower our customers to select the optimal technology for their specific needs. Whether you prioritize the contamination-free, low-maintenance benefits of sealless pumps or the enhanced operational safety and versatility of sealed pumps, our dual approach ensures that you don’t have to compromise on performance or reliability. This comprehensive product offering is a testament to our commitment to continuous improvement and customer-centric innovation. It reflects our understanding that the best engineering solutions are those that are tailored to the demands of each unique application, not a one-size-fits-all approach.

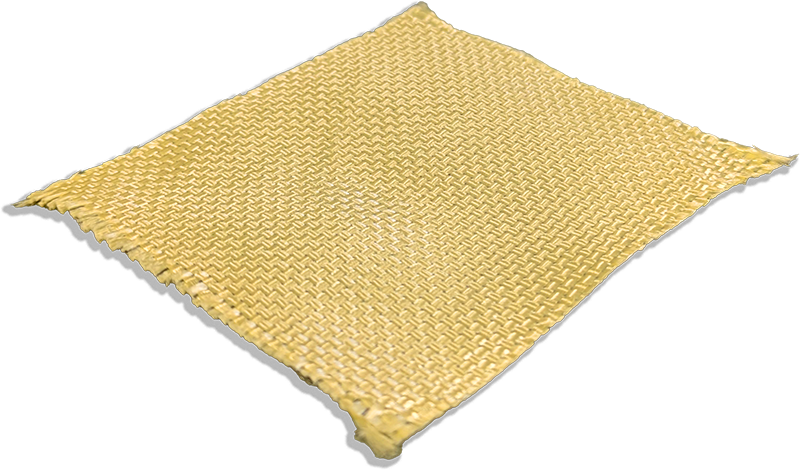

Excellence begins with the finest ingredients. Since 1990, we've embraced one guiding principle for sourcing raw materials—invest without compromise. Our use of premium components guarantees exceptional product quality while delivering unparalleled value.

Focused on Quality

When you need non metallic ANSI pumps that deliver impeccable performance, look no further. Our state-of-the-art, completely vertically integrated factory means every step from design to production, quality testing to final delivery is meticulously controlled in-house. This unparalleled oversight guarantees:

- Unmatched Quality: Our integrated process ensures each pump meets and exceeds ANSI standards, offering precision-engineered solutions that withstand the toughest industrial conditions.

- Cost-Effective Excellence: By streamlining production without reliance on external suppliers, we pass significant savings directly to you, without compromising quality.

- Reliability and Durability: With full control over every phase of manufacturing, ABM Industrial pumps are built to last, even in challenging and corrosive environments.

- Tailored Solutions: Our commitment to innovation allows us to adapt quickly to your specific needs, ensuring that every pump is perfectly suited to your application.

For over 30 years, our pumps have been a trusted name in the industrial pump industry, with a heritage that dates back to the founding of Innomag in the 1990s. With our decades of expertise and a commitment to innovation, we’ve established ourselves as a leading provider of high-quality pumps and solutions for a wide range of applications, from oil and gas to chemical and industrial processing. The name may be new, but our commitment to quality and our customers is unwavering.

© Copyright 2025 ABM Industrial - All rights reserved.